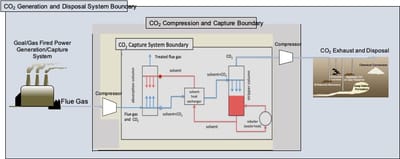

Carbon Dioxide Capture Technologies

Creative, low cost Solutions

About

While the latest projections by the US Energy Information Agency show rapid growth in the use of renewable fuels even by 2050 at least fifty percent of the electricity generation is still expected to be from fossil-fueled plants. Electricity generation currently contributes approximate 32% of the total US CO2 emissions. At present there are more than 2,000 power plants of which at least 50 of them have generating capacity greater that 1,500 MW. Currently the capital and operating costs of CO2 capture is a barrier to project development and financing let alone the fact that they typically impose a 20-40% parasitic loss of electrical generation.

CDOTECH is focused on demonstrating feasibility of new process technologies to lower the costs and size production scale facilities.

Services

Financial

CDOTECH can provide and execution of the financial analyses of the CAPEX and OPEX of the process technologies

Learn MoreTeam

Gregory McRae

CEO

Founder of CDOTECH and is responsible for overall management of the company and its scientific directions.

Zachary Ronan

Chief Technology Offices

He is responsible for identifying and incorporating the latest computing, networking and sensor technologies into CDOTECH. He also leads prototype developments.

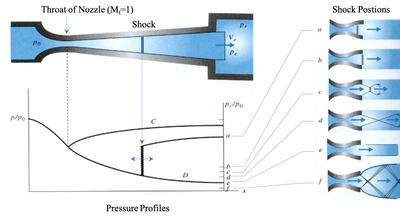

LAVAL NOZZLE

Compressible Fluid Dynamics

Even elementary textbooks on fluid dynamics describe the flow of water through converging diverging nozzles. These nozzles usually have a contraction that accelerates the flow and forms a shock down-stream from the throat. The sudden pressure change that occurs across the shock can lead to the formation of vapor bubbles by a process called hydrodynamic cavitation. As the bubbles move down stream, and collapse, the vapor can internally reach very high temperatures and pressures. When the bubbles collapse their energy is often sufficient to erode metal surfaces often seen on the tips ship propellers. These phenomena are well known.

At present even much less is known about what is happening inside the bubbles when chemistry is involved especially if there are interactions at the interface with the surrounding fluid that in turn affects heat and mass transfer from the bubble vapor to the fluid.

SPEED OF SOUND IN TWO PHASE FLOWS

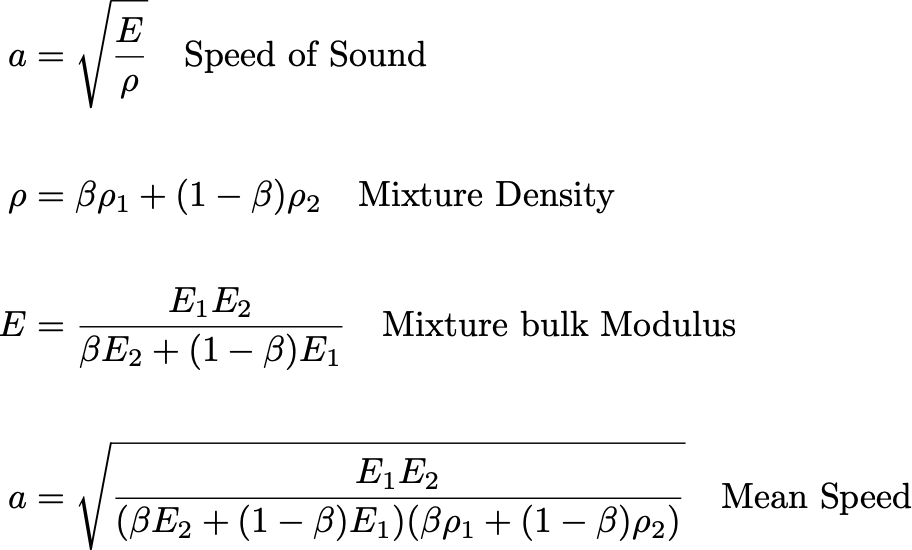

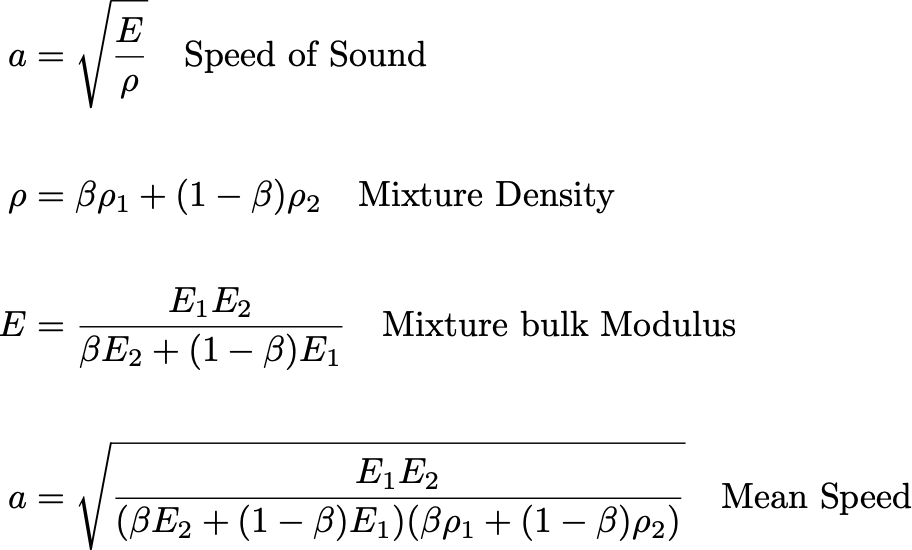

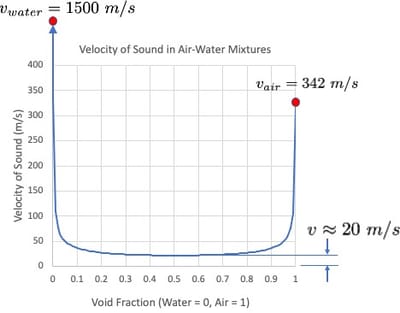

What is less well is what happens in two phase flows. The fluid dynamics is more complex and, if there are already vapor bubbles in the incoming flow, the shock speed is very much lower than either of the two components alone. With a 50% bubble volume in the incoming flow the shock speed of the mixture is ~20 m/s compared to the air value of 340 m/s and in water 1,500 m/s. Calculations of the speed of sound involve the densities of the components, their bulk moduli (E1,E2)

At present even much less is known about what is happening inside the bubbles when chemistry is involved especially if there are interactions at the interface with the surrounding fluid that in turn affects heat and mass transfer from the bubble vapor to the fluid..

At present even much less is known about what is happening inside the bubbles when chemistry is involved especially if there are interactions at the interface with the surrounding fluid that in turn affects heat and mass transfer from the bubble vapor to the fluid..

Articles

Contact

- Ballantyne Business Center

- 13850 Ballantyne Corporate Place Suite 500, Charlotte, NC 28277